Bearing Manufacturer & Supplier

Specialize in ball bearings, roller bearings, thrust bearings, thin section bearings etc.

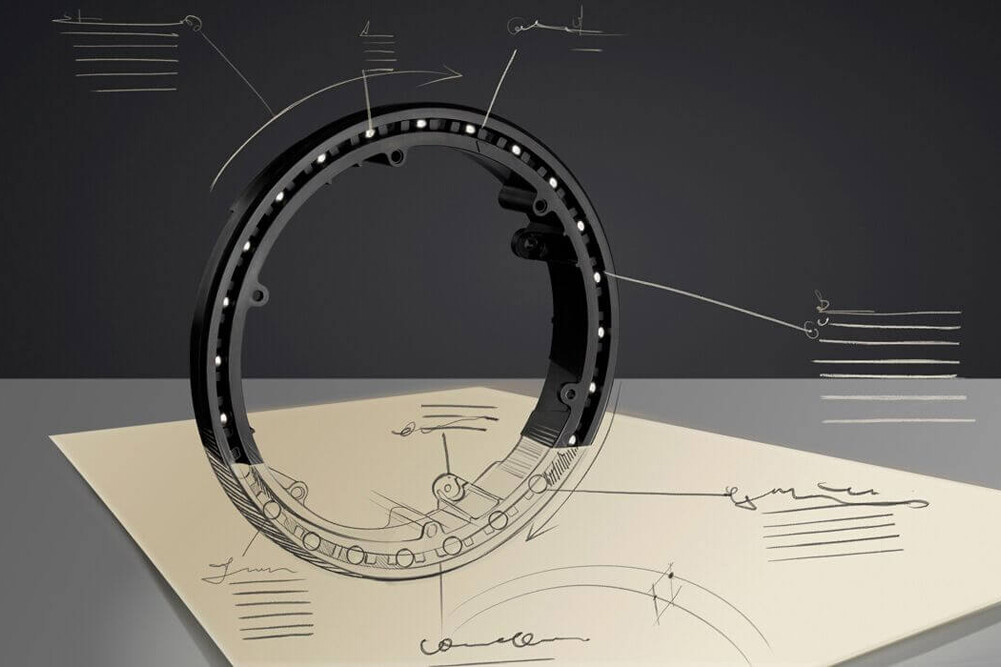

Guide to Thin Section Bearing Materials

Thin-section bearings are bearings whose cross-section width and thickness are equal. The same cross-section size can match a variety of different inner diameters. Unlike standard bearings, as the inner diameter of the bearing increases, the width and thickness also increase proportionally, thin-section bearings increase the inner diameter and the cross-sectional size remains unchanged. This guide aims to introduce the materials of thin-section bearings and provide constructive suggestions for you to purchase suitable bearings.

Table of Contents

ToggleAdvantages of thin section bearings

The thin section bearing series includes 9 cross-section sizes (ranging from 3/16″ to 1″) combined with bore sizes (ranging from 1″ to 40″). Thin-section materials 52100 chromium steel and 440C stainless steel can also be chrome plated. Of course, some thin-section bearings can be equipped with seals or dust covers, grease, custom cages and other options. There are three different types of thin section bearings; deep groove ball bearings, angular contact ball bearings and four point contact ball bearings. Compared to standard bearings, thin sections enable efficient design optimization to reduce overall costs. Especially in the fields of medical equipment, optical equipment, infrared scanning equipment and robots, where installation space and weight are key considerations, thin sections can meet the needs in terms of reducing installation space and weight.

Materials for thin section bearings

Different applications have different requirements for thin-section bearing materials. If the raw material of the bearing is not suitable, causing early failure of the bearing or other problems, then there is no point in purchasing the bearing. Likewise, if standard bearings meet your performance needs, purchasing bearings made of higher quality materials will increase the purchase cost. Thin section bearings of the correct material are important for your application. Below are some commonly used raw materials for thin-section bearings, as well as the advantages and applications of these materials.

Chrome steel

Chromium steel is also known as carbon steel, and this material is one of the most common raw materials for manufacturing bearings. GCr15 bearing steel is a high carbon low alloy steel containing chromium. Due to its compositional properties, this material has excellent strength and fatigue properties at operating temperatures below 200°C. This property makes GCr15 chromium steel an ideal choice as raw material for most thin-section bearings.

C | Si | Mn | Cr | Mo | P | S | Ni | Cu | Ni+Cu |

0.95 ~ 1.05 | 0.15 ~ 0.35 | 0.25 ~ 0.45 | 1.40 ~ 1.65 | ≤ 0.10 | ≤ 0.025 | ≤ 0.025 | ≤ 0.30 | ≤ 0.25 | ≤ 0.50 |

GCr15 is the most commonly used high-chromium bearing steel with high hardenability and high and uniform hardness after heat treatment. The wear resistance is better than GCr9, the contact fatigue strength is high, and it has good dimensional stability and corrosion resistance. Bearing steel has high requirements for smelting quality, and the content and distribution of sulfur, phosphorus and non-metallic inclusions need to be strictly controlled, because the content and distribution of non-metallic inclusions have a great impact on the life of bearing steel. The higher the inclusion level, the shorter the life. In order to improve the smelting quality, electric furnace smelting and electroslag remelting have recently been used. New processes such as vacuum smelting and vacuum consumable refining can also be used to improve the quality of bearing steel.

Tool Steel

M50 tool steel is a molybdenum type material. The addition of molybdenum gives the material greater resistance to wear and high temperatures. The chemical composition of M50 high-speed steel mainly includes carbon (C), molybdenum (Mo), steel (Fe), chromium (Cr), titanium (Ti), aluminum (Al) and other elements. Among them, the carbon content is between 0.80% and 0.85%, the molybdenum content is between 3.75% and 4.50%, the chromium content is between 3.75% and 4.50%, and the titanium content is between 1.75% and 2.25%. The aluminum content is between 0.75% and 1.25%. In addition, M-50 tool steel has good oxidation resistance and high pressure resistance. These properties make M-50 tool steel an ideal choice for bearings used in environments requiring increased resistance and high temperatures.

Stainless steel

If the working environment of your bearing is a very high temperature or a clean room, then stainless steel as the raw material of the bearing is ideal to meet your needs. Stainless steel has better corrosion and chemical resistance than standard steel. Stainless steel is therefore a good choice for applications where there is any potential for contamination (such as food processing or semiconductor equipment manufacturing). In addition, stainless steel bearings can better maintain their mechanical properties under special environments such as high temperature, high speed, and high load, making them durable. The most common stainless steel for thin-section bearings is SS440.

440C stainless steel has the following chemical composition: Carbon (C) 0.95-1.20%, Chromium (Cr) 16-18%, Molybdenum (Mo) 0.75%, Manganese (Mn) 1%, Silicon (Si) 1% , phosphorus (P) is 0.040%, sulfur (S) is 0.030%. The higher carbon content of 440C gives it good edge properties and wear resistance. It also has excellent corrosion resistance and can resist the erosion of a variety of chemically corrosive media. Through heat treatment and quenching, it can reach a hardness of HRC 58-60, which is the hardest material among all stainless steels. 440C has a high chromium content and has excellent corrosion resistance in most acidic and alkaline environments.

Ceramics

All-ceramic thin-section bearings are less common, but hybrid thin-section bearings made of metal inner and outer rings, cages, and ceramic balls are a common option. Ceramics have some special advantages over other steel bearings. First, ceramics are a lighter material than steel. Since the density of ceramic rolling balls is lower than that of steel and the weight is much lighter, the centrifugal effect on the outer ring during rotation can be reduced by 40%, thereby greatly extending the service life. Ceramic balls, especially silicon nitride balls, have the characteristics of low density, high hardness, low friction coefficient, wear resistance, self-lubrication and good rigidity. They are especially suitable for rolling elements (inner and outer rings) of high-speed, high-precision and long-life hybrid ceramic ball bearings. for metal).

Generally, the inner and outer rings are made of bearing steel (GCr15) or stainless steel (AISI440C), and the ceramic balls can be made of ZrO2, Si3N4, or SiC materials. In addition, ceramics have higher corrosion resistance and high temperature performance up to 1800 degrees. Unlike steel, ceramic is also non-conductive, making it a good choice for certain electrical applications. However, ceramic balls are expensive than standard metal balls. Of course, this extra cost may be worth it, and the price depends on the exact performance you need and environmental requirements.

Thin Section Bearing Cage Material

The cage is an important part of thin-section bearings and has the following three functions:

Guide and drive the rolling elements to roll on the correct raceway.

The cage separates the rolling elements at equal distances and distributes them evenly on the circumference of the raceway to prevent the rolling elements from colliding and rubbing with each other during operation.

Combine the rolling elements with a ferrule to prevent the rolling elements from falling off.

There are three common options for thin-section bearing cage materials: steel cages, brass cages and nylon cages, of which we focus on the latter two.

Brass cage

1. Brass cage types: stamped and solid cages, among which stamped cages are only suitable for small and medium-sized thin-section bearings.

2. Materials: Brass plate, brass castings and brass forgings; brass has high tensile strength, and its mechanical strength is equivalent to that of steel plate stamping cages, but its density is relatively small and its limit speed is high.

3. Advantages: Not affected by lubricants, including synthetic oils and greases.

4. Use restrictions: Brass cages cannot be used in situations above 300°C, and are not suitable for ammonia (such as cooling), because ammonia will cause seasonal breakage of brass;

5. Working temperature: The working temperature is lower than 300℃.

Nylon cage

Nylon cage is a new generation product currently replacing copper cage and iron cage. Compared with metal cage, it has great advantages.

1. The nylon cage is light in weight, making the bearing flexible. If used in electrical appliances or power-consuming products, it plays a great role in energy saving.

2. It has low noise and is the first choice for silent bearings, especially for electrical products that have high noise requirements.

3. It can effectively extend the service life of the bearing, reducing the friction between the metal cage and the steel ball. The nylon cage plays a great role in extending the life of the bearing.

Conclusion

There are several different factors that affect the application of thin-section bearings. Kaydon is the most famous thin-section bearing brand in the world, but it is very expensive. The price of a Reali-Slim® series of small bearings even reaches than 3,000 US dollars. Fortunately Aubearing manufactures equivalent Kaydon bearings that cost you a tenth of the original price, or even less. Of course, Aubearing has the ability to tailor thin section bearing assemblies to your specific needs. If you are not sure which thin section bearing to choose, consult the experts at Aubearing today.