Bearing Manufacturer & Supplier

Specialize in ball bearings, roller bearings, thrust bearings, thin section bearings etc.

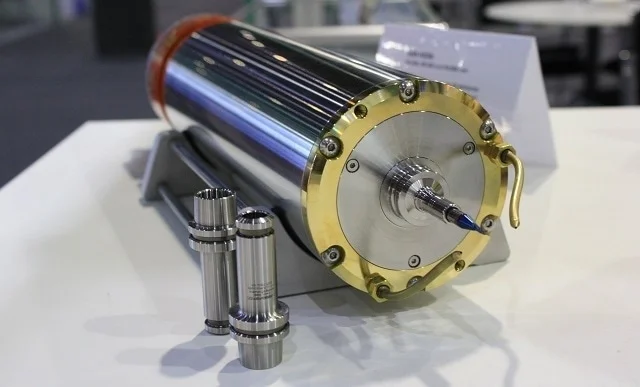

Machine Tool Spindle Bearing Solutions

In addition to developing a wide range of super precision ball bearings, AUB prides itself on providing the best OEM solutions and advice on machine tool spindle bearings. In 2020, AUB was commissioned to conduct a pilot spindle upgrade project with one of the best machining center manufacturers in China. After a series of tests, research, modifications and joint efforts, we successfully launched the bearing prototype in a pilot project, which led us into the machine tool spindle bearing supplier market.

Table of Contents

ToggleWith years of expertise and knowledge in:

Heat treatment and grinding of spindle related components

Careful selection of mating parts, such as bearing bore against shaft OD

Thorough post assembly characteristic checks & endurance run

Machine tool spindle

Machine tool spindles are rotating components used to hold and drive cutting tools or workpieces on lathes, mills, and other machine tools. They use belt, gear, motorized, hydraulic or pneumatic drives and are available in a variety of configurations. For example, the barrel assembly is mounted in a fixed housing, while the angled spindle is configured to allow right-angle or adjustable tool rotation. Some machine tool spindles are mounted in solid blocks or box-like housings. Others are bolted through flanges or feet on the bottom of the housing.

Most machine tool spindles suitable for cutting tool heads have a Morse taper or other standardized machine taper. Multiple spindle heads are used to speed up machining operations and repetitive precision work, such as close tolerance center holes.

Applications

Machine tool spindles are used in a variety of applications.

Boring spindles are used in the machining of internal diameters.

Drilling spindles provide good thrust capacity and radial load ratings.

Grinding spindles are used with grinding wheels for precision, size and surface finishing.

Wheel dressing spindles are suitable for the truing, dressing, contouring, and re-profiling of abrasive grinding wheels.

Tapping spindles are used with taps to create internal threads.

Tuning spindles are designed for horizontal or vertical lathes and turning centers.

Hobbing spindles are used in the cutting of gear tooth profiles.

Milling spindles are used with a wide variety of machining tools and operations.

The demand for bearings in the machine tool industry

With the advent of CNC technology, machine tools promise to be precise, efficient and reliable than ever. To remain competitive, machining companies are investing in high-quality bearings that ensure top equipment performance. The overall purpose of spindle bearings is to enhance and simplify spindle motion to ensure optimum machine speed and precision. Bearings affect the speed, rotation, vibration, accuracy and temperature of machine tools, which in turn alters the quality of the final product.

Bearings typically consist of a ring or a series of rings with balls or other rolling elements that streamline the motion of the spindle in the desired direction. Depending on the equipment and the movement required, bearings can be designed to facilitate the movement of the spindle on both transverse and radial axes. They must be able to withstand the load pressures, temperatures and high speeds of machine tool spindles.

Machine tool spindles and spindle bearings work together

In the machine tool industry, the spindle is a key component for forming materials through high-speed rotation and pressure. With the advancement of modern machinery, processing equipment needs to be faster, precise and durable than ever before. Bearings are key components that guide and enhance the motion of the spindle. The use of high-quality bearings increases the efficiency and reliability of machine tool spindles, resulting in increased production and reduced mechanical wear.

4 types of bearings for machine tool applications

Bearings for machine tool spindles fall into four different categories. Each bearing design has characteristics that make it suitable for a particular application, and it is important to understand how each works so you can choose the best bearing for your equipment.

Angular contact ball bearings are the most common spindle bearings. They are rolling bearings consisting of one or rows of rolling balls between concentric grooved rings. They can be used to carry radial and axial loads in one direction, and their axial load carrying capacity depends on the angle at which the load contacts the bearing. The larger the angle, the higher the load capacity.

Popular in industrial machinery, radial bearings are rolling bearings primarily used to carry loads on radial shafts. Like angular contact bearings, they consist of an inner and outer ring between which rolling balls are fitted; however, radial bearings can carry loads in both axial directions, which makes them compact than angular contact bearings general.

Roller bearings enhance motion by using rolling cylinders instead of balls. They are mainly used to support radial loads and axial loads in one direction parallel to the axis. They can be used in medium to high speed applications to reduce friction and increase equipment speed.

Thrust ball bearing

Thrust ball bearings are designed to support heavy, high-precision thrust loads, providing extremely precise axial support parallel to the drive shaft, but little radial support. Rolling elements can be balls, rollers or needles, depending on the application. They are particularly suitable for applications such as propeller engines, which allow heavy loads to move freely and easily parallel to the axis.

As the market continues to demand increased machine tool output with greater efficiency and precision, bearings are also evolving to meet stringent industry demands. With than 20 years of experience, AUB Bearings is proud to provide excellent bearing solutions to customers worldwide. We understand that every system has different requirements, and our knowledgeable staff is dedicated to helping our customers find the perfect bearing for their application. We offer the most advanced steel alloys and sealed bearings on the market for enhanced performance, durability and resistance to even the toughest applications and harshest environments.