Bearing Manufacturer & Supplier

Specialize in ball bearings, roller bearings, thrust bearings, thin section bearings etc.

Everything About Bearing Life

Bearing life is one of the key factors that determine the life of mechanical equipment. After determining the working space of the bearing, for a given shaft bore diameter, it is possible to find standard bearings with different outer diameters and widths. As the bearing outer diameter and width increase, the dynamic load capacity increases accordingly, thereby increasing the bearing’s rating life. Once the load and speed of the bearings have been determined, the question now becomes: “How many hours of rated life does a well-designed machine require?” Sometimes this is dictated by specific industry standards or company policies based on the industry and customer’s location. of. In an industry, it may be perfectly acceptable for end users to service equipment once a year, replacing bearings, seals, etc. In another industry, bearings have a service life of at least ten years. The frequency of use of the equipment also needs to be considered when determining the minimum expected rated life value.

Table of Contents

ToggleAUbearing - a leading bearing manufacturer

AUbearing manufactures than 8,000 bearing types used in a variety of industries in the United States and around the world. Industrial-grade bearings manufactured by Aubearing not only provide long service life according to rolling fatigue standards, but bearing construction must also be considered based on the application to prevent shock, overload and occasional high-speed excursions. To this end, the design of each bearing is optimized.

Bearing dynamic load capacity – C

Based on the rated dynamic load being a pure radial load of constant direction and constant magnitude (for radial bearings) or a central axial load (for thrust bearings), a basic rated life of 1 million revolutions can be obtained in this case. The value of this important bearing parameter C is shown in every bearing table except for crane hook bearings. The basic dynamic load rating indicates the bearing’s ability to withstand rolling fatigue and is specified as the basic dynamic radial load rating (< a i=3>Cr) for radial bearings, and the basic dynamic axial load rating (Ca) for thrust bearings. These values have been defined by associations such as the American Bearing Manufacturers Association (ABMA) and the International Organization for Standardization (ISO) to calculate dynamic loads on bearings. Bearing dynamic loading is used to predict the rating life of each bearing at its expected load and speed. Generally speaking, a bearing can only withstand a maximum operating load equal to half of its bearing dynamic load capacity.

Static Capacity - Co

Bearing static capacity Co is the maximum load that can be safely applied to a non-rotating bearing without causing damage to subsequent bearing operation. It is based on the calculated contact stress at the center of the most heavily loaded rolling element in contact with the inner ring. The stress levels for the three types of bearings are:

– Self-aligning ball bearings are 4600 MPa (667,000 psi)

– 4200 MPa (609,000 psi) for all other ball bearings

– All roller bearings are 4000 MPa (580,000 psi)

Bearing rating life calculation

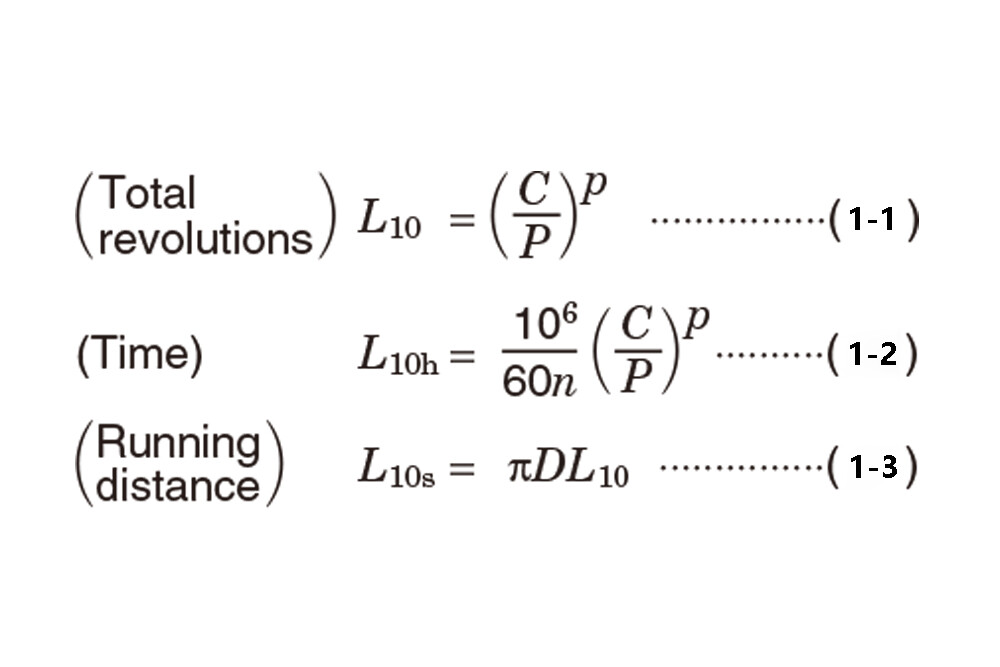

The basic rating life L10 refers to the usage conditions of high-quality manufacturing bearings with a service life of 90% reliability in normal use. The inside of the bearing is made of bearing steel materials specified by JIS or a standard design made of equivalent materials. The relationship between basic dynamic load rating and dynamic load. The equivalent load and basic rating life of the bearing can be expressed by equation (5-1). This life calculation formula is not applicable to bearings C0 that are affected by factors such as plastic deformation of the raceway and rolling element contact surfaces due to extremely high load conditions (when P exceeds the basic static load rating) (refer to the basic static load rating and static equivalent load) or 0.5C) or conversely, for bearing load conditions affected by factors such as raceway contact surfaces and rolling elements sliding due to extremely low slip. This is the time that a set of apparently identical bearings will go through or exceed before fatigue spalling develops. The basic formula for calculating the rated life of bearing L10 is (1-1):

To calculate the basic rating life of a bearing, equation (1-2) is used for constant speed operation; when the bearing is used in railway rolling stock or automobiles, in terms of travel distance (km), equation (1-3) is used.

Therefore, the dynamic equivalent load is P and the rotational speed is n; then you can refer to the bearing specification table to select the bearing size most suitable for the specific purpose. C can calculate the basic dynamic load rating formula (1-4); the recommended service life of the bearing varies depending on the machine using the bearing, as shown in Table 1-5 Recommended service life of the bearing (reference) <a i=2>.

Refer to

The service life coefficient (fh) and the rotational speed coefficient nf are calculated according to equation (1-2) as follows:

For reference only, the values of fn, fh and L10h can be easily obtained by using the nomogram attached to this catalog as a simplified method.

[Reference] Speed (n) and its coefficient (f< a i=4>n), service life coefficient (fh) and basic rated life (L10h)

Combined radial and thrust loads

All ball bearings and roller bearings can withstand large axial thrust loads. When combined radial and axial loads occur, the “equivalent bearing load” P used in the rating life formula needs to be calculated. This calculation can be somewhat complex as it depends on the relative magnitudes of the radial and thrust loads to each other and the contact angle created by the bearing. It would be too difficult to demonstrate the calculation of P for all bearing types shown. For tapered roller bearings, the “K” thrust coefficient is used. For any rating life calculations requiring a combination of radial and thrust loads, please contact Aubearing.

Radial cylindrical roller bearings with opposing flanges on the inner and outer rings have a limited ability to withstand thrust loads over the length of the rollers. Acceptable thrust loads are those using roller ends and flanges for intermittent thrust and positioning purposes. Since any thrust loads will be perpendicular to the radial loads and different bearing contact surfaces will be used, thrust loads along the roller length are not a factor in bearing life calculations.

Varying loads and speeds

Bearings do not operate at a constant load or speed in many applications, and it may not be economical to select a bearing with a specific rated life (in hours) based on worst-case operating conditions. Typically, duty cycle can be defined for various operating conditions (load and speed) and the percentage of time under each operating condition. Related situations also occur in some machines that produce reciprocating motion. Further, these two examples can be combined for several expected operating conditions with reciprocating motion and different peak loads and speeds. Calculating the rated life for load and speed changes first requires calculating the L10 rated life for each operating condition of the duty cycle. Next, use the formula below to combine the individual L10 life with the rated life over the entire duty cycle.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

T1, T2, T = percentage of time under different conditions, expressed as a decimal n

T1 + T2 + … T< /span> = 1n

Lp1, Lp2, L = Life in hours per constant load and speed cycle pn

Oscillating load

The bearing does not completely rotate during operation but has an oscillation amplitude. We can use the following formula to calculate the lower equivalent radial load of the bearing:

Pe = Po x (β/ 90)1/e

Pe = equivalent dynamic radial load

Po = actual oscillating radial load

β = swing angle in degrees

e = 10/3 (roller bearing) 3.0 (ball bearing)

Separate radial and thrust loads

In some applications, bearings are subject to very high radial and thrust loads. For applications subject to both types of loading, a better design is to provide separate bearings for radial or thrust loads. If this is the case, the machine designer must be careful to ensure that the radial bearings only carry radial loads and the thrust bearings only carry thrust loads. A good way to achieve this is to use a cylindrical roller bearing with a straight race in the “radial” position, since this bearing cannot handle any thrust forces. A pair of angular contact bearings or large angle tapered roller bearings are usually good choices for carrying thrust loads, but they must be protected from any radial loads. One way to achieve this is to make the outer ring fit very loosely into the housing: typically 0.5mm/0.020in. to 1.0 mm/0.040 in.

Adjustment Factors for Bearing Life

Bearing life adjustment factors allow OEMs to better predict the actual service life and reliability of the bearings you select and install in your equipment. The adjusted L10 rated life is calculated using the following formula:

Lna = a1 x a2 x a3 x L10

Lna = adjusted rated life

a1 = reliability life adjustment coefficient

a2 = life adjustment factor for special bearing characteristics (e.g. material)

a3 = Life adjustment factor for operating conditions, lubrication, cleanliness, etc.

The life adjustment factors a1, a2 and a3 can theoretically be greater or less than 1.0, depending on their evaluation.

Reliability life adjustment - a1

Equipment manufacturers need to improve the reliability of selected bearings to predict longer service times. The a1 factor shown below is used to increase the reliability value. If the L10 value calculated using the a1 factor is unacceptably low, a bearing with a greater dynamic load capacity will need to be selected.(Citation from JIS B 1518:2013)

| Reliability, % | Lnm | α1 |

|---|---|---|

| 90 | L10m | 1 |

| 95 | L5m | 0.64 |

| 96 | L4m | 0.55 |

| 97 | L3m | 0.47 |

| 98 | L2m | 0.37 |

| 99 | L1m | 0.25 |

| 99.2 | L0.8m | 0.22 |

| 99.4 | L0.6m | 0.19 |

| 99.6 | L0.4m | 0.16 |

| 99.8 | L0.2m | 0.12 |

| 99.9 | L0.1m | 0.093 |

| 99.92 | L0.08m | 0.087 |

| 99.94 | L0.06m | 0.080 |

| 99.95 | L0.05m | 0.077 |

Life adjustment factor for special bearing characteristics - a2

Particularly in recent years, there have been many improvements in bearing design and manufacturing that have been confirmed in life tests, resulting in improved L10 times. Some of these improvements are:

Improve surface finish

Improved materials and heat treatment

Rollers and raceways

Life correction factor: αISO

a) Systematic approach

The various effects on bearing life are interdependent. The systematic method of calculating corrected life has been evaluated as a practical method for determining the life correction factor αISO (see Figure 5-1). The life correction coefficient αISO is calculated by the following formula. There are diagrams for each bearing type (radial ball bearings, radial roller bearings, thrust ball bearings and thrust roller bearings). (Each figure (Figures 5-2 to 5-5) is quoted from JIS B 1518≤50. ISOα

Note that in actual use, this is set to the lifetime modification factor: 2013.)

Figure 1-1 System solution

1-2 Life correction coefficient αISO (radial ball bearing)

1-3 Life correction coefficient αISO (radial roller bearing)

1-4 Life correction coefficient αISO (thrust ball bearing)

1-5 Life correction coefficient αISO (thrust roller bearing)

b) Fatigue load limit: Cu

With the same quality, as long as the load condition does not exceed a certain value and in an environment with good lubrication conditions, lubrication cleanliness level and other operating conditions, the life of the bearing is theoretically unlimited. For bearings made of generally high-quality materials and manufacturing quality, the fatigue stress limit is reached when the contact stress between the raceway and rolling elements is approximately 1.5 GPa. If one or both of the material quality and manufacturing quality is lower, the fatigue stress limit will also be lower. The term “fatigue load limit” refers to the fatigue load limit. Cu is defined as “the bearing load that just reaches the fatigue stress limit under the heaviest load “raceway contact” ISO 281:2007. And is affected by factors such as bearing type, size and material. Regarding special bearings and not listed in this catalog For detailed information on the fatigue load limits of other bearings, please contact Aubearing.

c) Pollution factor: ec

If solid particles from contaminated lubricant become trapped between the raceways and rolling elements, indentations may form on one or both of the raceways and rolling elements. These indentations will cause localized pressure increases, thus shortening life. The shortened life due to lubricant contamination can be calculated according to the degree of contamination, that is, the contamination coefficient ec. Shown in the Dpw table is the pitch circle diameter of the ball/roller set, simply expressed as < /span>: inner diameter) Relevant special For details such as lubrication conditions or detailed investigation, please contact JTEKT. d: outer diameter, D)/2. (d=(D+pwD

| Contamination level | ec | |

|---|---|---|

| Dpw<100mm | Dpw≧100mm | |

| Extremely high cleanliness: The size of the particles is approximately equal to the thickness of the lubricant oil film, this is found in laboratory-level environments. | 1 | 1 |

| High cleanliness: The oil has been filtered by an extremely fine filter, this is found with standard grease-packed bearings and sealed bearings. | 0.8~0.6 | 0.9~0.8 |

| Standard cleanliness: The oil has been filtered by a fine filter, this is found with standard grease-packed bearings and shielded bearings. | 0.6~0.5 | 0.8~0.6 |

| Minimal contamination: The lubricant is slightly contaminated. | 0.5~0.3 | 0.6~0.4 |

| Normal contamination: This is found when no seal is used and a coarse filter is used in an environment in which wear debris and particles from the surrounding area penetrate into the lubricant. | 0.3~0.1 | 0.4~0.2 |

| High contamination: This is found when the surrounding environment is considerably contaminated and the bearing sealing is insufficient. | 0.1~0 | 0.1~0 |

| Extremely high contamination | 0 | 0 |

d) Viscosity ratio: κ

The lubricant forms an oil film on the roller contact surface, separating the raceways and rolling elements. The state of the lubricating oil film is expressed by the viscosity ratio κ, which is the actual kinematic viscosity ν at the operating temperature divided by the reference kinematic viscosity. For detailed information on lubricants such as greases and lubricants containing extreme pressure additives, contact JTEKT. Greater than 4, equal to 4, and less than 0.1 are not applicable. κ A is shown in the following formula.

Service life of a bearing system consisting of two or bearings

Most machines use two or bearings on one shaft, and often have two or shafts. All bearings in a machine are considered a bearing system. For business purposes, it is important for manufacturers to understand the reliability of their machines or system longevity. This evaluation process considers the important factor of combining the L10 life of all bearings in the system to answer the question: “How long will the machine run with ninety percent reliability?” “Simply put, the system L10 reliability will be lower than the lowest individual L10<a i=6> rated life. The calculation formula of the system rated life is as follows:

[example]

When a shaft is supported by two roller bearings with service lives of 50 000 hours and 30 000 hours respectively, the rated life of the bearing system supporting the shaft is calculated as follows: Formula (1-11):

This equation shows that these bearings as a system have a shorter rated life than bearings with shorter lifespans. This fact is important in estimating bearing service life in applications where two or bearings are used.

Recommended service life of bearings in different applications

Since a longer service life does not always contribute to economical operation, the most suitable service life for each application and operating conditions should be determined. For reference, the empirically determined recommended service life based on application is described in the table below.

| Operating condition | Application | Recommended service life (h) |

|---|---|---|

| Short or intermittent operation | Household electric appliance, electric tools, agricultural equipment, heavy cargo hoisting equipment | 4000~8000 |

| Not extended duration, but stable operation required | Household air conditioner motors, construction equipment, conveyers, elevators | 8000~12000 |

| Intermittent but extended operation | Rolling mill roll necks, small motors, cranes | 8000~12000 |

| Motors used in factories, general gears | 12000~20000 | |

| Machine tools, shaker screens, crushers | 20000~30000 | |

| Compressors, pumps, gears for essential use | 40000~60000 | |

| Daily operation than 8 hr. or continuous extended operation | Escalators | 12000~20000 |

| Centrifugal separators, air conditioners, air blowers, woodworking equipment, passenger coach axle journals | 20000~30000 | |

| Large motors, mine hoists, locomotive axle journals, railway rolling stock traction motors | 40000~60000 | |

| Paper manufacturing equipment | 100000~200000 | |

| 24 hr. operation (no failure allowed) | Water supply facilities, power stations, mine water discharge facilities | 100000~200000 |