Bearing Manufacturer & Supplier

Specialize in ball bearings, roller bearings, thrust bearings, thin section bearings etc.

The Ultimate Guide to Roller Bearing Applications

Roller bearings are a type of bearings widely used in various machinery and equipment. They support and guide rotation, reduce friction, bear loads, automatically align, and large-scale industrial manufacturing, allowing mechanical equipment to operate normally and maintain high efficiency and efficiency. Reliable and stable working conditions play an important role in mechanical operation. This blog will introduce the relevant knowledge of roller bearings in detail to help readers better understand this important mechanical component.

Table of Contents

ToggleHow roller bearings work

Roller bearings are mainly composed of inner rings, outer rings, rolling elements and cages. The inner and outer rings are usually made of high-carbon steel, and the surface is quenched to improve hardness and wear resistance.

The rolling element is the core element in the bearing. It can be cylindrical, conical or spherical. It reduces friction by rolling between the inner and outer rings and supports the rotating shaft. The function of the cage is to keep the position of the rolling elements stable and prevent them from colliding with each other.

When the rotating shaft rotates through the rolling elements between the inner ring and the outer ring, due to the shape characteristics of the rolling element, it can roll between the inner ring and the outer ring, thereby reducing the friction and allowing the rotating shaft to rotate easily. At the same time, the number and arrangement of rolling elements will also affect the bearing capacity and service life of the bearing.

Types of roller bearings

There are many types of roller bearings, and they can be divided into different types according to different classification methods. According to the shape of the rolling elements, roller bearings can be divided into cylindrical roller bearings, tapered roller bearings, spherical roller bearings, etc.; according to the bearing structure, they can be divided into single-row bearings, double-row bearings, thrust bearings, etc.; according to the bearing load Direction, can be divided into radial bearings, thrust bearings and radial thrust bearings, etc. There are many types of roller bearings, and each type of roller bearing has its own unique characteristics and application range. The following is an introduction to the main types of roller bearings and their comparison:

Cylindrical roller bearings: The rollers of this type of bearing are usually arranged in parallel and mainly bear radial load, but can also bear a certain degree of axial load. They have high radial load carrying capacity and high rotational speeds. According to whether the ring has ribs or not, cylindrical roller bearings can be further subdivided into NU type, NJ type, NUP type, etc.

Tapered roller bearings

Tapered roller bearings: The rollers of this type of bearing are conical, so they can bear both radial and axial loads. They are usually used to withstand combined loads dominated by radial loads, and in the case of large cone angles, they can also bear combined loads dominated by axial loads. The separate design of the tapered roller bearing makes its installation and disassembly easier.

Spherical roller bearings

Spherical roller bearings: This type of bearing has two rows of rollers and is mainly used to bear large radial loads and axial loads in a single direction. They have an automatic self-aligning function that can compensate for shaft misalignment caused by deflection or misalignment of the shaft or housing. Spherical roller bearings can be divided into R type, RH type, RHA type and SR type according to different internal structures.

Thrust roller bearings

Thrust roller bearings: This type of bearing is mainly used to bear axial load, and its nominal contact angle is greater than 45°. Thrust roller bearings include thrust spherical roller bearings, thrust cylindrical roller bearings and thrust tapered roller bearings. They are designed to withstand axial loads as well as certain radial loads.

Roller bearing comparison

Cylindrical roller bearings and tapered roller bearings are excellent at carrying radial loads, but tapered roller bearings can also handle larger axial loads.

While bearing radial loads, spherical roller bearings have an automatic self-aligning function and can adapt to the deformation of the shaft or housing.

Thrust roller bearings are mainly used to bear axial loads and have high load-bearing capacity and rigidity.

When selecting the bearing type, the selection should be based on the actual working conditions and requirements to ensure the best performance and life of the bearing.

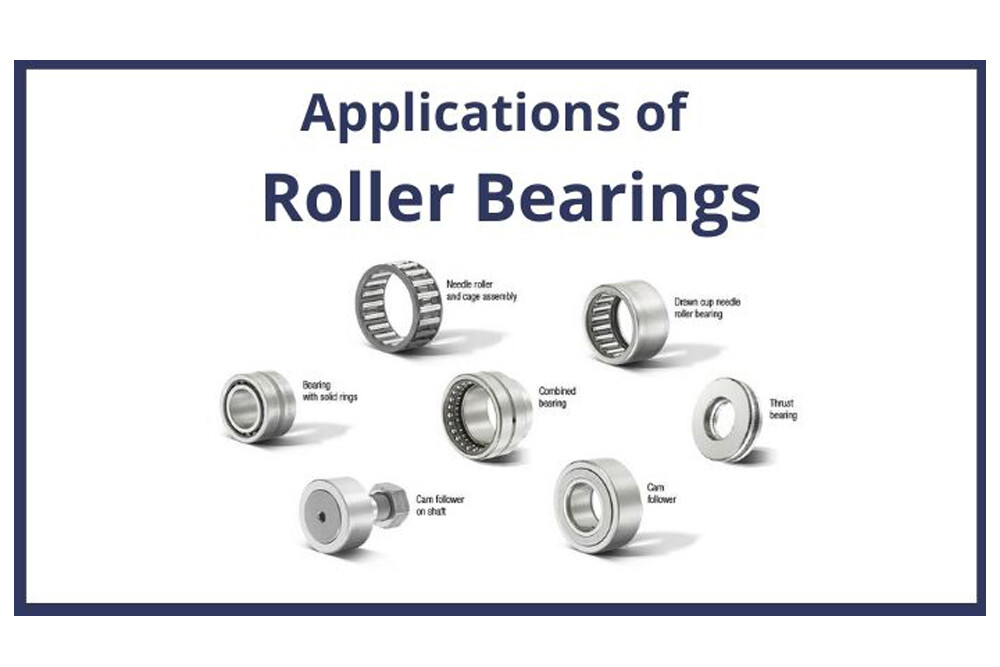

Applications of roller bearings

Roller bearings are widely used in various machinery and equipment, such as automobiles, trains, aircraft, machine tools, etc. In these fields, roller bearings play an important role, such as supporting rotating shafts, reducing friction, improving mechanical efficiency, etc. At the same time, with the continuous advancement of technology and changing application requirements, the design and manufacturing of roller bearings are also constantly improving and innovating. Roller bearings are used in a wide range of applications, and their high efficiency, high reliability and long life satisfy a variety of application needs. Here are some common application scenarios:

Automotive industry: Roller bearings are widely used in the automotive industry, such as transmissions, engines, transmission systems, etc. In these situations, roller bearings are used to support the rotating shaft, transmit torque and reduce friction, improving the performance and reliability of the car.

Railway transportation: Roller bearings are widely used in railway locomotives and EMUs, such as wheel bearings, suspension bearings, etc. These bearings need to withstand large loads and impacts, while also requiring high reliability and long life.

Aerospace: In the aerospace field, roller bearings are also widely used due to high-speed rotation and high-precision requirements. For example, main shaft bearings in aircraft engines, rotor bearings in helicopters, etc.

Industrial machinery: Roller bearings are widely used in industrial machinery, such as motors, reducers, pumps, compressors, etc. In these occasions, roller bearings are used to support the rotating shaft, transmit power and reduce friction, improving mechanical efficiency and reliability.

Medical equipment: In some medical equipment, such as medical centrifuges, dental drills, etc., roller bearings are also required. In these situations, roller bearings need to have high precision, low noise, and no pollution.

In short, as an important mechanical component, roller bearings are very important in terms of their working principle, type and application. Understanding the relevant knowledge of roller bearings can help us better understand their performance and applications, and provide useful reference for the maintenance and improvement of mechanical equipment.